How D3O®iP™ Technology is Changing Hand Protection

PIP® G-Tek® PolyKor™ D3O®iP™ Impact Gloves Win the 2024 OH&S Industrial Hygiene Award

---------------------------------------------------------------------------------------------------------------------------------------------

THE DIFFERENCE

What sets G-Tek® PolyKor™ D3O®iP™ work gloves apart from the rest is its low-profile design that combines maximum dexterity with ANSI/ISEA-138 Impact Level 3 compliance to deliver the thinnest hand protection on the market.

This is achieved by an exclusive 3D printed chevron pattern that is adhered directly onto a 13-gauge seamless knit cut-resistant shell. The result is a glove that offers enhanced hand mobility without sacrificing impact protection—effectively allowing for the use of less material to achieve equal or superior protection compared to standard TPR styles.

IMPACT-RELATED INJURIES

Impact-related hand injuries are one of the most common occupational hazards in the industrial work force. According to a study conducted by the U.S. Department of Labor, between the years 2021-2022, 23 percent of all work-related injuries involve severe impacts to the hands or fingers. Of those injuries, 63 percent were cuts, 13 percent were crush and 8 percent were avulsion, making hand injuries the most frequent of preventable workplace injuries.

In the oil and gas, mining, construction, manufacturing, and transportation industries, back-of-the-hand impact protection is critical as workers have increased exposure to hazards like crushing, bumps, bruising, pinching, cuts, and punctures that standard hand protection cannot sufficiently protect against.

THE DILEMMA

Traditional hand protection solutions have long faced a dilemma: achieving the necessary level of protection often means compromising comfort and dexterity. Breathability is a crucial factor, and traditional coatings often lack breathability, compelling users to depend solely on the liner on the back of the hand for air circulation. This situation is intensified when the back of the hand is encased in thick, non-porous blocks of Thermoplastic Rubber (TPR), eliminating any possibility for air to pass through.

From a dexterity perspective, impact-resistant gloves often require a thicker shell for support, typically made of natural or synthetic leather. However, many leather gloves offer zero grip, a significant disadvantage for workers in the oil & gas or manufacturing industries who need to manage slippery items such as chains, pipes, and other equipment coated with residual oil and grease. This lack of grip means that leather gloves are prone to slippage, reducing their effectiveness and increasing the risk of accidents, or even worse, propelling the wearer to remove their gloves completely.

FIGHTING THE STIGMA

TPR impact hand protection still has its place in the industry. One notable advantage of TPR is its ability to mold into complex shapes. This characteristic allows for the formation of flex points around the knuckles and fingers, ensuring that protection does not come completely at the expense of mobility.

PIP® provides an extensive selection of back-of-the-hand impact-resistant gloves, ensuring that workers have the proper hand protection to effectively complete tasks. TPR impact gloves hold a reputation as being well suited for their potential for low to moderate crush and cut hazards and need for shock absorption, but only when being used appropriately.

However, the widespread use of TPR for applications requiring precision brings about issues of comfort, dexterity and most importantly, compliance. Typically sewn onto gloves, TPR protectors not only adds bulk but also leads to durability issues due to stitch deterioration after extended periods of wear on the job. This method of construction has created a stigma within the industry: more protection requires more materials, inevitably leading to less dexterity and comfort for the wearer.

So, how can workers who need this elevated level of hand protection close the gap between performance and comfort?

LESS IS MORE

Enter D3O®iP™ technology, which has effectively “flipped the safety script” by using less material to deliver more – more protection, more comfort, and more dexterity. This approach ensures that the most crucial tools on any job site – the hands of the worker – are not only protected but are also comfortable to wear.

ELEVATED SAFETY COMPLIANCE

The solution is twofold. First, by integrating D3O®iP™ technology directly onto the glove material rather than relying on sewn-on components, it enhances the durability and the lifespan of the glove. Secondly, by opting for a foam nitrile palm coated seamless knit instead of leather, G-Tek® D3O®iP™ safety gloves can not only absorb and disperse fluids under pressure, but the lightweight knitted glove shell significantly improves grip and tactility. This approach protects hands from impact and ensures that the gloves remain breathable, comfortable, and effective even in the most challenging conditions, boosting wearer acceptability and decreasing the chances of workers removing their gloves and becoming more susceptible to injuries.

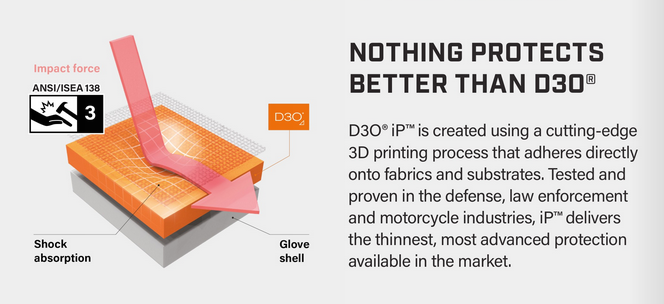

NOTHING PROTECTS BETTER AGAINST IMPACTS THAN D3O®iP™

By developing the G-Tek® PolyKor™ D3O®iP™ glove line that meets ANSI/ISEA 138-2019 Level 3 Impact Protection, PIP® has set a new benchmark for impact hand protection.

The innovative iP™ (Impact-Printed) approach leverages a 3D printing process that adheres directly onto outer fabrics and substrates, establishing an incredibly durable bond traditional TPR methods cannot match. The result is a glove that offers enhanced hand mobility without sacrificing impact protection—effectively allowing for the use of less material to achieve equal or superior protection compared to standard TPR styles.

UNMATCHED DEXTERITY

What truly distinguishes D3O®iP™ from other impact-resistant gloves is the combination of maximum dexterity with ANSI/ISEA-138 Impact Level 3 compliance achieved by incorporating an exclusive chevron pattern on a 13-gauge coated seamless knit cut glove. This unique design is engineered to mimic the natural biomotion of the human hand, offering a level of comfort and flexibility seldom experienced in the industry. This approach contrasts with traditional cut and sewn leather driver gloves, which, despite their widespread use, often fall short of providing operators with the necessary freedom of movement and tactile sensitivity required for precise tasks.

Whether the task involves managing sharp materials or working in environments where lacerations and abrasions are a constant threat to safety, D3O®iP™ gloves provide the necessary defense against injuries, all while ensuring that the wearer's hands remain as agile and unrestricted as possible.

SELECTING THE LEVEL OF PROTECTION

Ensuring comfort and compliance can be difficult when choosing the most optimal hand protection for your application as there are many factors to consider. D3O®iP™ gloves represent a harmonious blend of protection, comfort, and dexterity, setting a new standard for what workers can expect from their protective gear. By incorporating this breakthrough technology, PIP® continues to lead the way in developing solutions that address real-world needs of workers, while also prioritizing both safety and usability.

+shop for G-Tek® PolyKor® D3O® iP™ Gloves here

Monday – Friday 8:30am – 4:30pm EST

Call or Click Today

Samples. Volume Discounts. Questions. Samples.

Toll-Free +800-274-4637 | +716-668-4001 | [email protected] | MDSassociates.com

"We Want You To Return Home Safely...Every Day! "™